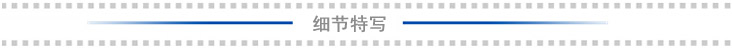

1. Improve the utilization rate of the board. The cutting machine uses a milling cutter to cut the material, which can be turned in any direction and cut into irregular shapes. The push table saw must cut the material all the way to the bottom, resulting in low board utilization rate. With the help of self layout and disassembly software for automatic optimization, the average utilization rate of each board is 2.7-2.8 square meters.

2. Save labor by having two people operate one push table saw and one person operate several cutting machines.

3. Reduce labor intensity, operate 60 sheets of board per day with a push table saw, which results in a heavy workload and high wages for workers, making it difficult for technical workers to manage.

4. The cutting speed is fast, and the cutting machine works continuously. The push table saw pushes and stops, and the boards move back and forth, increasing the workload of workers.

5. The dust on the cutting machine is small, and the suction effect of the cutting machine is much better than that of the push table saw.

6. Automatic loading and unloading is fully automatic and an optional function, with an area of 150-200 square meters for 8 hours per day

A regular cutting machine covers an area of 120-150 square meters for 8 hours a day. The machine is manually operated for loading and unloading, allowing workers to take breaks during processing, greatly reducing the intensity of manual labor.

This machine is operated in a foolproof manner, with all calculations done by a computer, zero errors, and zero failure rate. Easy to operate, any worker can directly start their job after 3-5 hours of training from the manufacturer

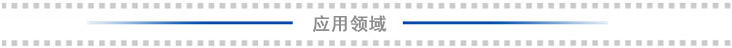

Woodworking industry, furniture decoration, advertising industry, processing materials

| National Unified Sales Hotline: 400-6587-688 |

| Jinan Huawei CNC Equipment Co., Ltd |

| Address: No. 18-1 Tonghua Road, Jinan City, Shandong Province Postal Code: 250000 Phone: 0531-88620266 Fax: 0531-88276988 Mobile phone: 15853195586 E-mail: cncmachine@jnhwcnc.com |